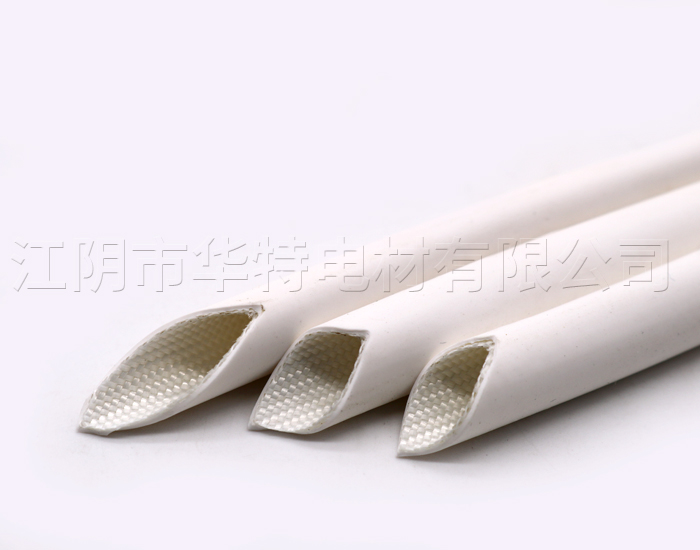

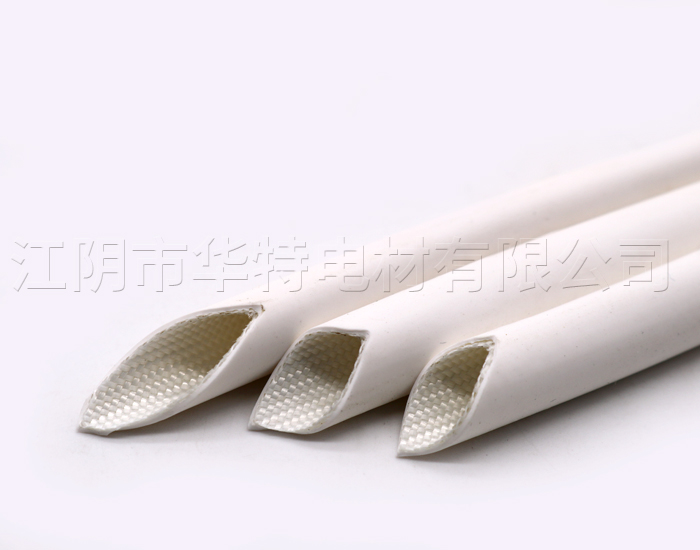

Introduction of inner fiber and outer plastic:

Introduction of inner fiber and outer plastic:

Silicone rubber glass fiber sleeve is made of non-alkali glass fiber woven tube, extruded silicone rubber, vulcanized by heating. This kind of casing has excellent dielectric property, high heat resistance and excellent cold resistance, softness and elasticity, and is also widely used in wiring insulation and mechanical protection of class H electric machinery and special electrical appliances.

Performance parameters:

|

Name

|

Inner fiber and outer plastic

|

Specifications

|

|

|

Serial number

|

Project

|

Performance indicators

|

Note

|

|

1

|

Breakdown voltage (wall thickness greater than 1.0)

|

>7000v

|

|

|

2

|

Continuous service temperature range

|

-10℃+180℃

|

|

|

3

|

Thermal aging

|

180℃, 6 hours, no crack

|

|

|

4

|

Hydrolytic stability

|

No sticky, no deformation, no softening

|

|

|

5

|

Temperature resistance

|

180℃±2℃ 168 hours ≥1/2 the original voltage value

|

|

Tolerance range

|

Inner diameter

|

Wall thickness

|

|

Nominal

|

Tolerance

|

Tolerance

|

|

1.5-2.0mm

|

±0.2mm

|

±0.05mm

|

|

2.5-3.0mm

|

±0.25mm

|

±0.05mm

|

|

3.5-5.0mm

|

±0.35mm

|

±0.05mm

|

|

6.0-9.0mm

|

±0.5mm

|

±0.1mm

|

|

10.0-12.0mm

|

±0.7mm

|

±0.1mm

|